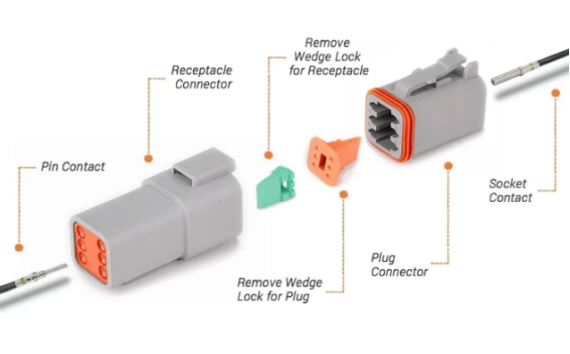

DTP04-4P-L012 Male 4 Pins Waterproof mining vehicle Connector DTP connetcor

|

OEM Part Number |

DTP04-4P-L012 |

|

OEM Series |

DTP |

|

MinMax Part Number |

1150000506 |

|

MinMax Family |

MCS078 |

|

Connection Type |

Wire to Wire, Wire to Board |

|

Number of Positions |

004 |

|

Number of Rows |

1 |

|

Hybrid |

No |

|

Contact Tab Size (mm) |

2.5mm |

|

Male/Female |

Male |

|

Sealable |

Yes |

|

Body Color |

Gray |

|

Housing Material |

PA66 |

|

Nominal Voltage Architecture (V) |

12,24 |

|

Operating Temperature Range |

-40℃~120℃ |

|

Certification |

ISO9001, RoHS, REACH, TS16949 |

Overview

As the core component for achieving sealing protection in Deutsch DTP series connectors, it is mainly installed at the contact part between the connector shell and the mating surface, and at the entrance where the wire penetrates into the shell. It can accurately fill the gaps between various components, prevent external pollutants such as water, dust, and oil from invading the inside of the connector, and at the same time prevent the grease or other media inside the connector from leaking. It is a key sealing element to ensure the long-term stable operation of DTP series connectors under complex working conditions, and is widely compatible with different specifications of products in this series.

Deutsch Features

✔Made of oil-resistant and anti-aging silicone rubber or nitrile rubber, with good elasticity, low compression set, and not easy to harden or crack after long-term use.

✔Can maintain stable sealing effect at -40°C to 125°C, and can achieve IP67 protection level when used with connectors.

✔Has good chemical corrosion resistance, and can resist the erosion of various industrial solvents and automotive fluids.

✔Has strong compatibility with connector shells and wires, not easy to fall off after installation, and the sealing effect is long-lasting and reliable.

Application

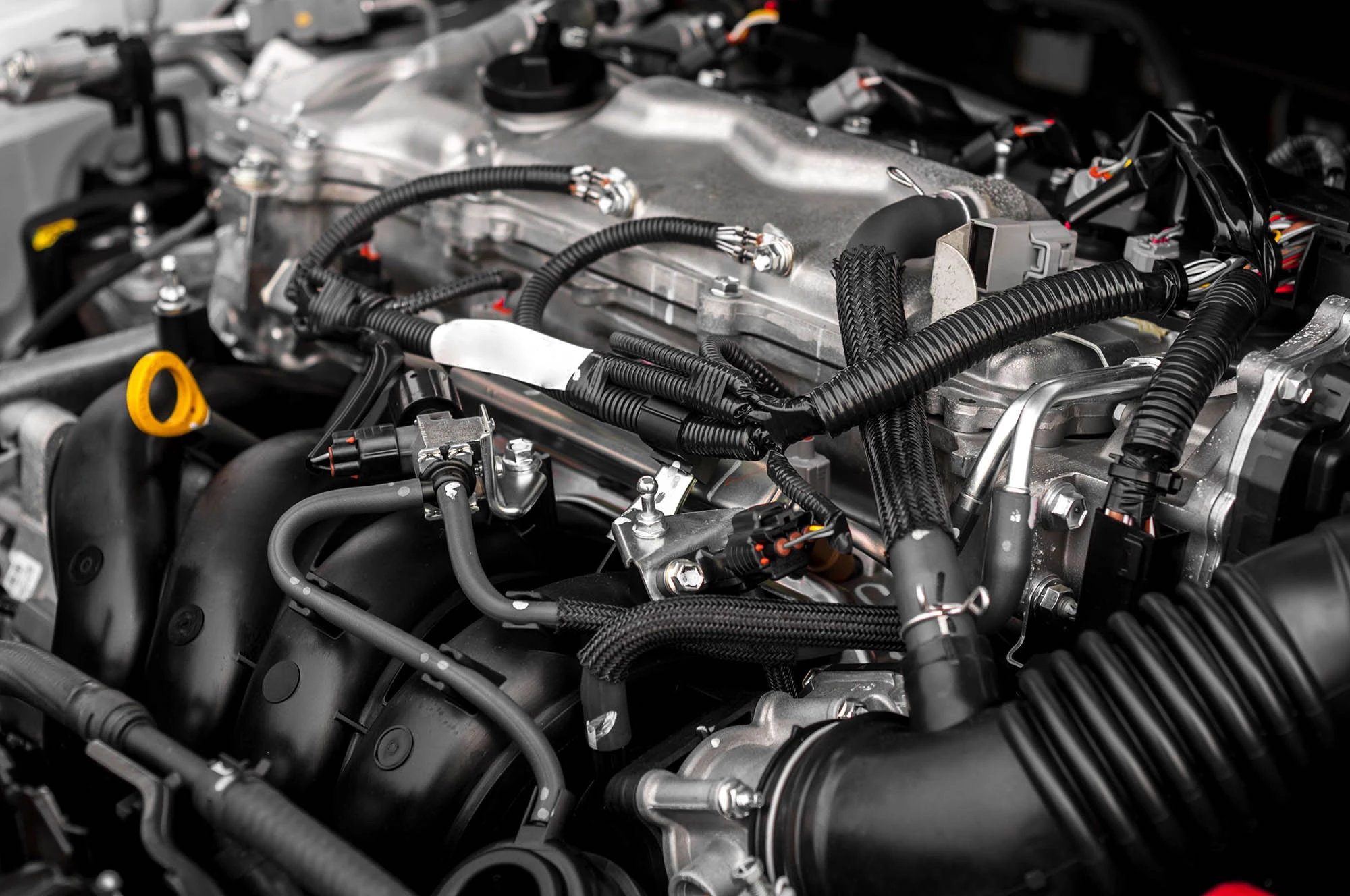

On the Engine

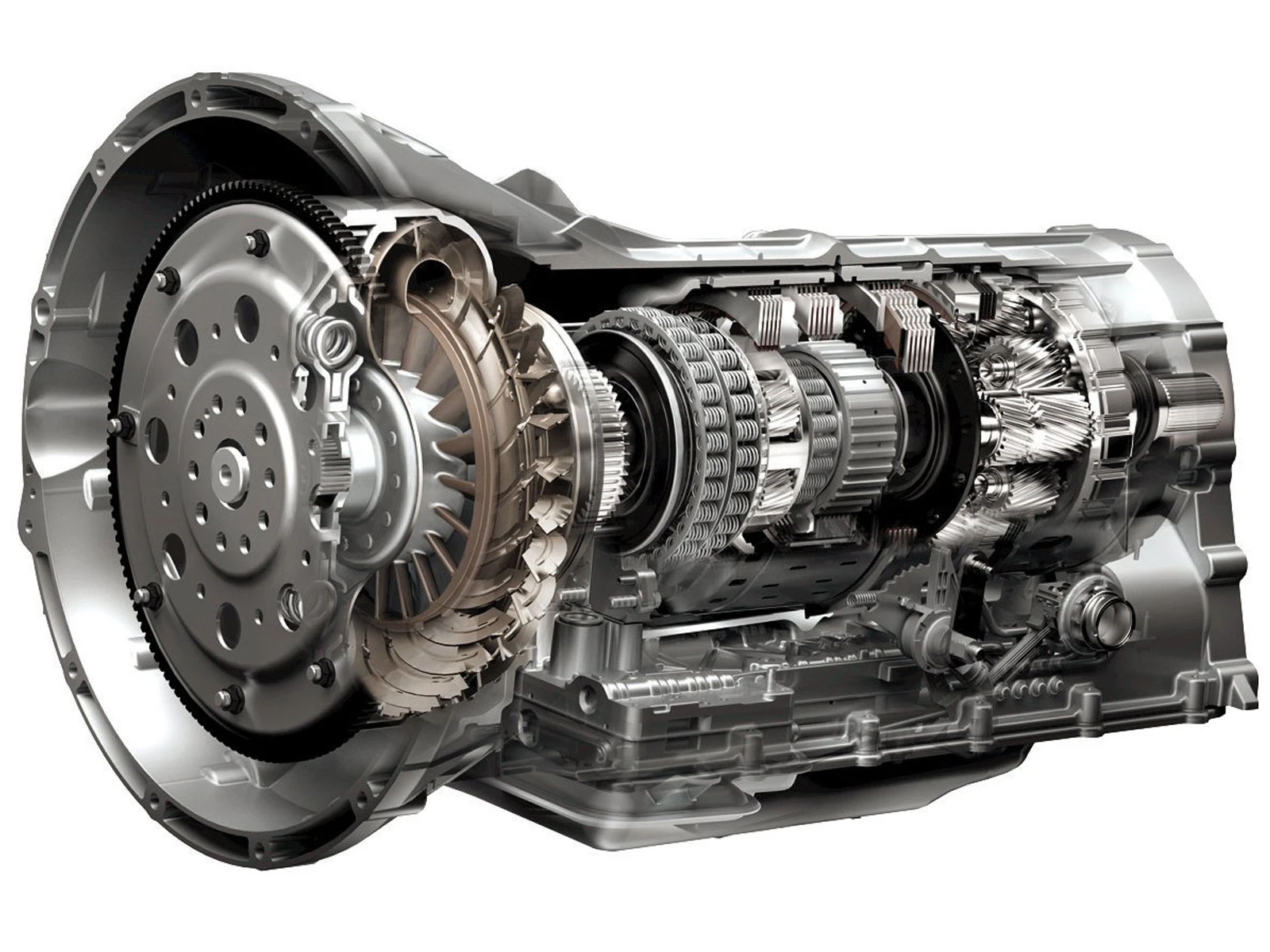

On the transmission

Automotive Under the Hood

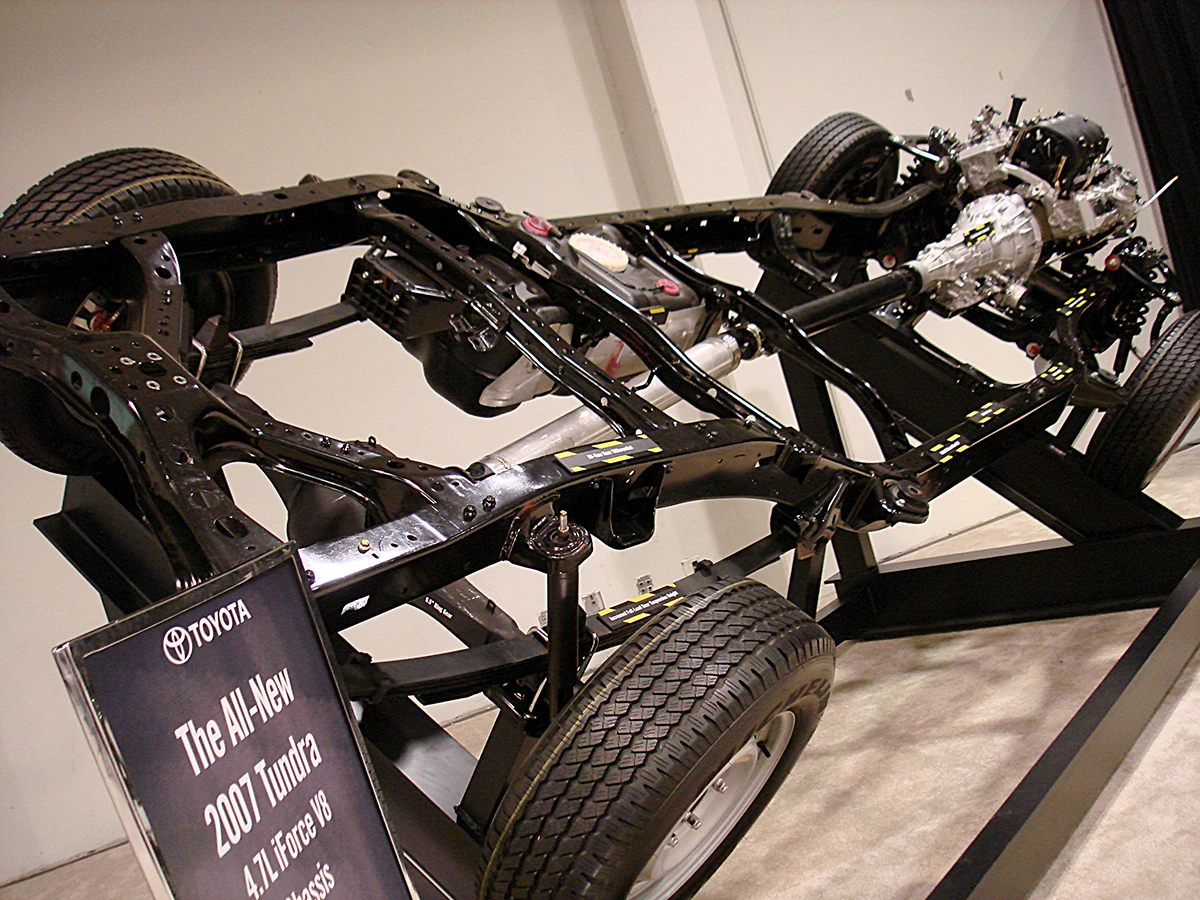

On the Chassis

In the Cab

in the heavy duty

Our Workshop Overview

EDM Mirror Processing

EDM Parts

Slow-feeding wire cut machine

CNC Machine

Plastic Injection Machine

Automatic production Line

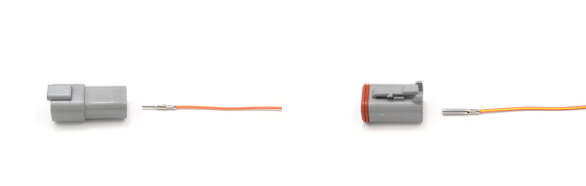

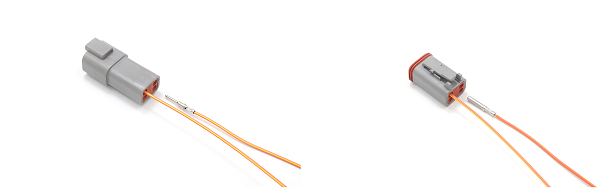

How to instructions

Step 1 Crimp the terminal and do the pull-out test to make sure the crimpings are completed

step 2 Crimping terminal and matched connector

Step 3 Insert the terminal to the connectors

Step 4 finished the connecting.