0462-209-16141 Female Solid Contact 2mm² 14AWG for Body Electrical System ,Chassis Electrical System,14AWG

|

OEM Part Number |

0462-209-16141 |

|

OEM Series |

DT |

|

MinMax Part Number |

1240000024 |

|

MinMax Family |

/ |

|

Tab Size (mm) |

1.5mm |

|

Male/Female |

Female |

|

Sealable |

No |

|

Wire Size (mm²) |

/ |

|

Wire Size (AWG) |

14AWG |

|

Crimp Type |

/ |

|

Material |

Brass |

|

Interface Plating |

Nickel |

|

Load Current |

14(AWG)–16(A) |

|

Nominal Voltage Architecture (V) |

12,14 |

|

Operating Temperature Range |

-40℃~120℃ |

|

Certification |

ISO9001, RoHS, REACH, TS16949 |

Overview

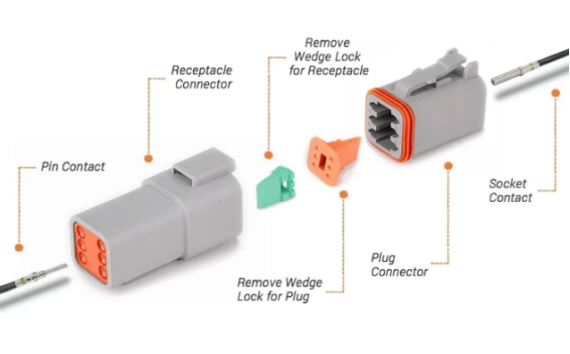

Several contacts are used interchangeably across most connector product lines.

This commonality improves performance, reliability, and maintainability by reducing changes in the assembly of the wire harness.

The use of the same contact systems eliminates many of the failures reported in harnesses where hundreds of different terminations are used.

The solid contacts are designed for use with larger wire size and heavy-duty applications.

Stamped & formed contacts are designed for use where wire termination costs are of primary concern without sacrificing reliability of electrical circuits.

Deutsch Features

✔High universality: Several contacts are interchangeable across most connector product lines

✔Reduced failures: Unified contact systems eliminate failures from multiple terminations

✔Classified design: Solid contacts for large wire sizes/heavy-duty use; stamped & formed contacts balance termination costs and circuit reliability

✔Enhanced performance: Reduces wire harness assembly changes, improving performance, reliability and maintainability

Application

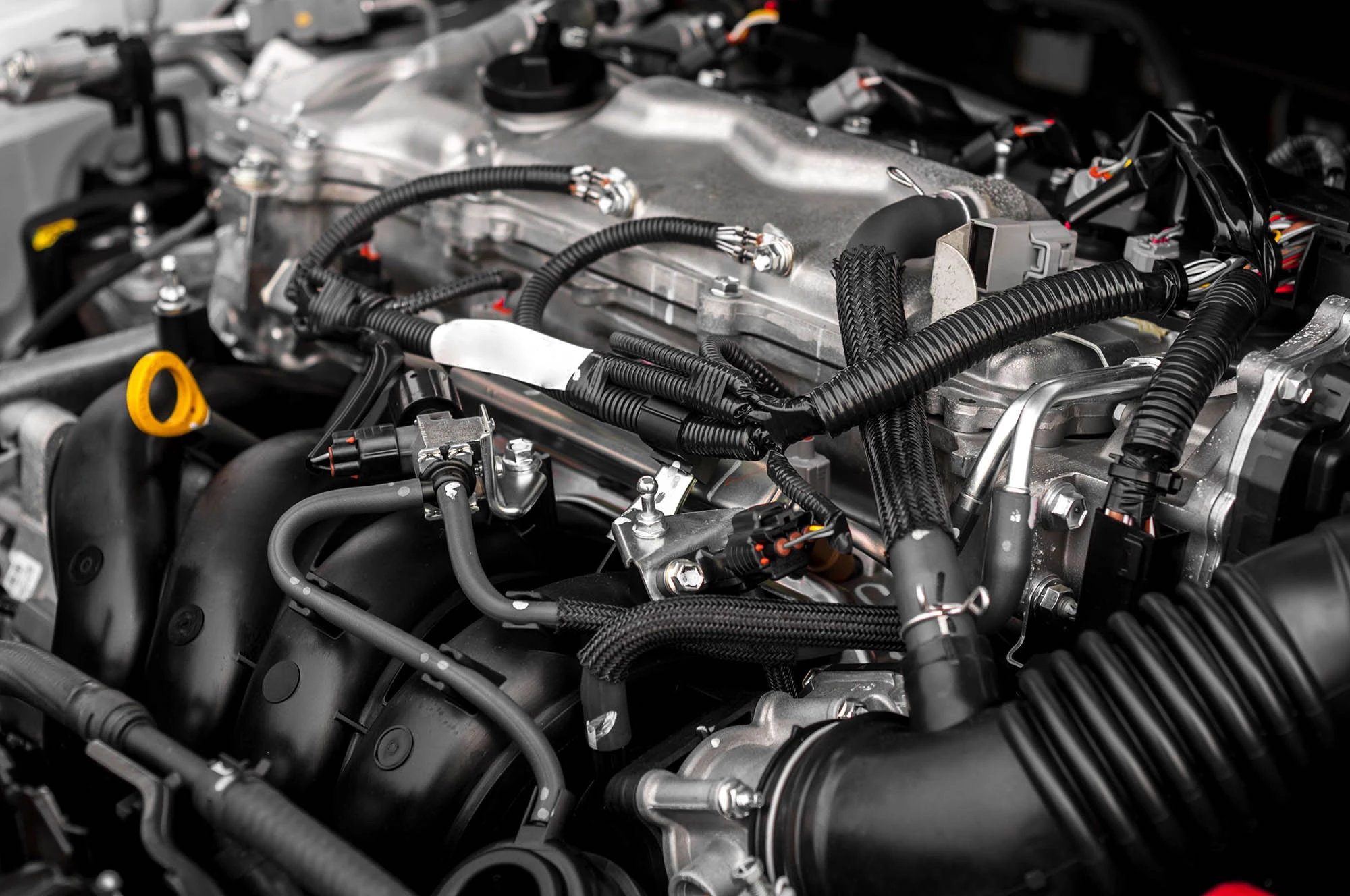

On the Engine

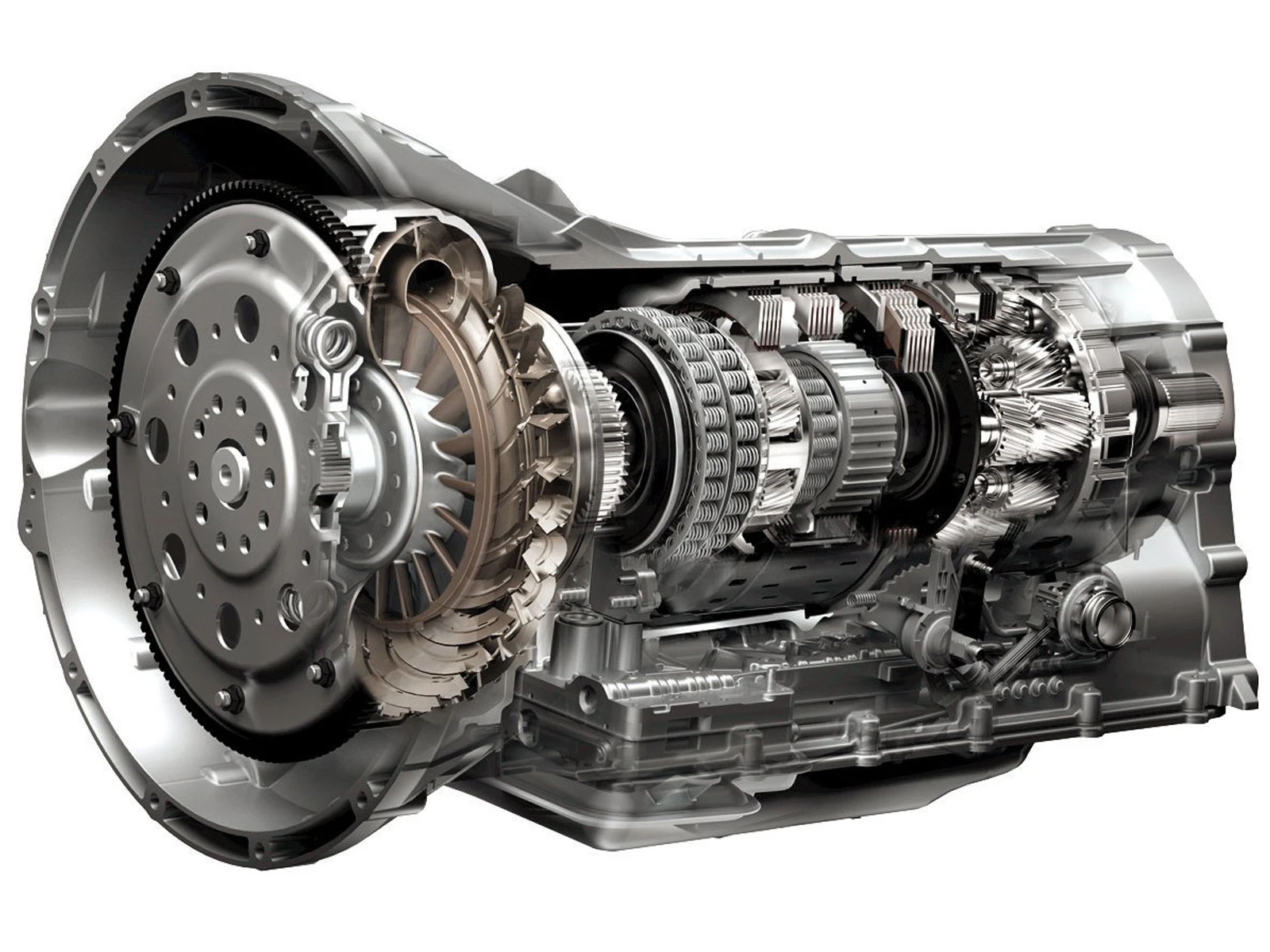

On the transmission

Automotive Under the Hood

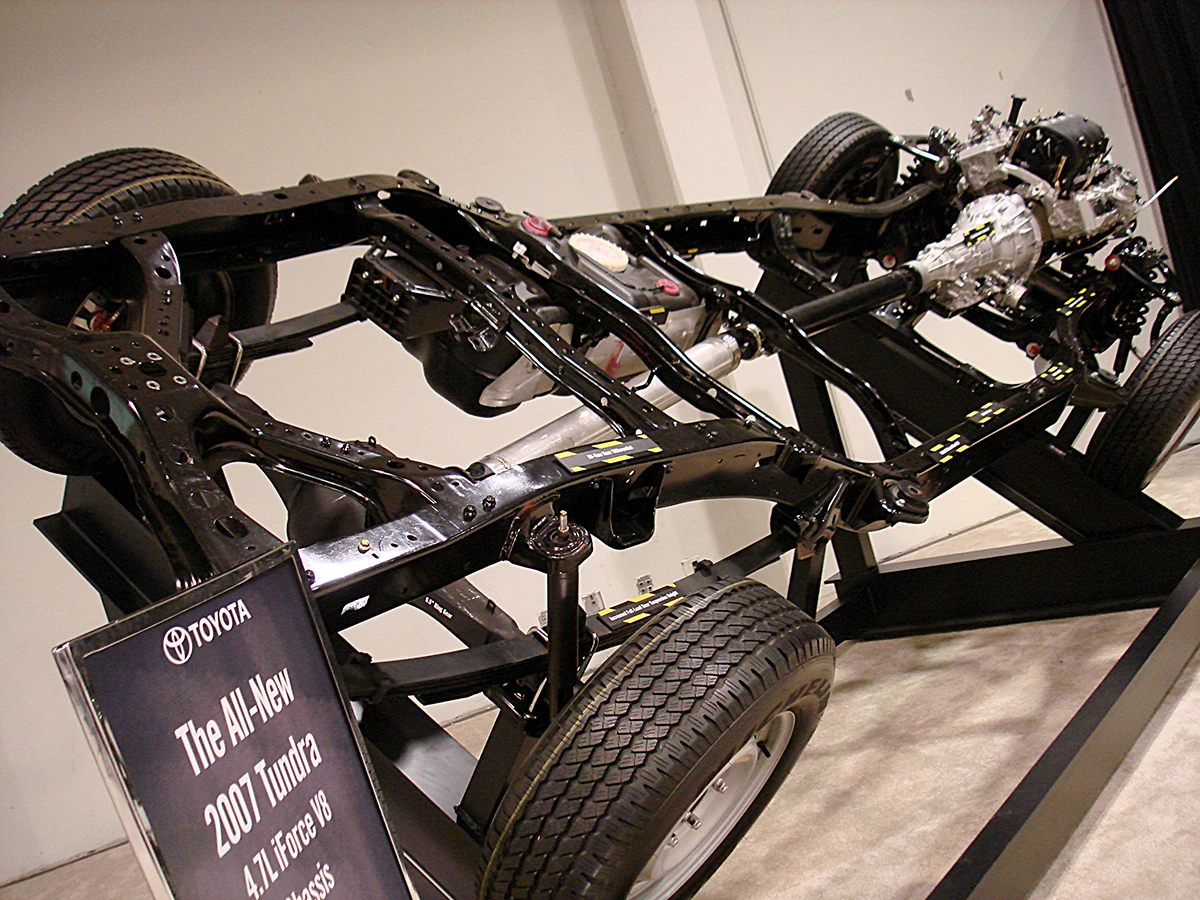

On the Chassis

In the Cab

in the heavy duty

Our Workshop Overview

EDM Mirror Processing

EDM Parts

Slow-feeding wire cut machine

CNC Machine

Plastic Injection Machine

Automatic production Line

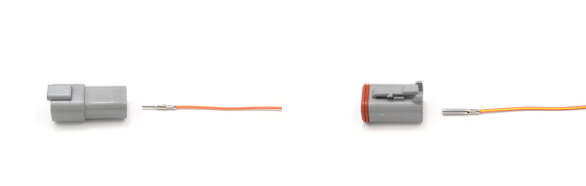

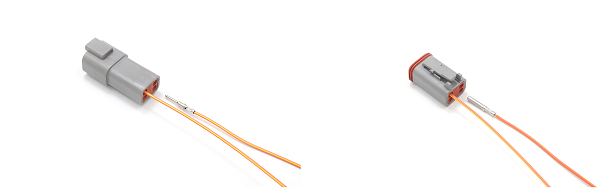

How to instructions

Step 1 Crimp the terminal and do the pull-out test to make sure the crimpings are completed

step 2 Crimping terminal and matched connector

Step 3 Insert the terminal to the connectors

Step 4 finished the connecting.