0460-010-20141 Male Solid Contact 18-16AWG nickel plating

|

OEM Part Number |

0460-010-20141 |

|

OEM Series |

DEUTSCH Common Contact |

|

MinMax Part Number |

1240000036 |

|

MinMax Family |

/ |

|

Tab Size (mm) |

1.2mm |

|

Male/Female |

Male |

|

Sealable |

No |

|

Wire Size (mm²) |

0.75 – 1.5 |

|

Wire Size (AWG) |

16 – 18 AWG |

|

Crimp Type |

/ |

|

Material |

Brass |

|

Interface Plating |

Gold |

|

Load Current |

16 – 18(AWG)–7.5(A) |

|

Nominal Voltage Architecture (V) |

16,18 |

|

Operating Temperature Range |

–55℃~125℃ |

|

Certification |

ISO9001, RoHS, REACH, TS16949 |

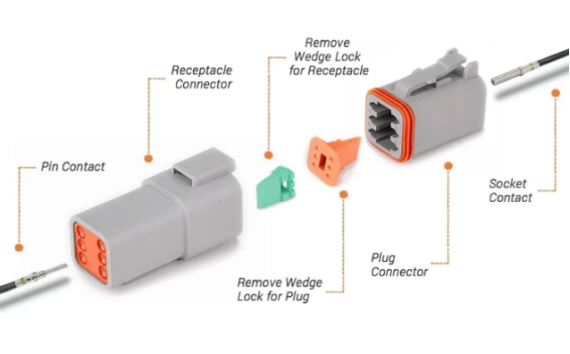

Overview

As the core conductive component of the Deutsch DTM series connector, the terminal undertakes the task of accurately connecting external wires with the internal conductive structure of the connector, and is a key medium for current and signal transmission. Its design is compatible with the low and medium current specifications of the series connectors, ensuring tight connection through the optimized contact structure, and can maintain stable conductive performance in environments with frequent vibration, effectively reducing transmission loss and providing reliable support for the efficient operation of the entire electrical system.

Deutsch Features

✔Made of high-conductivity copper alloy material, with excellent conductivity, reducing energy loss during current transmission.

✔The surface is tinned, with strong oxidation resistance, and can maintain low contact resistance for a long time.

✔Adopts precision crimping process, firmly connected with wires, and the pull-out force meets industry standards to ensure stable connection.

✔Compact structural design, suitable for the narrow space of DTM series connectors, with smooth insertion and removal and reliable contact.

Application

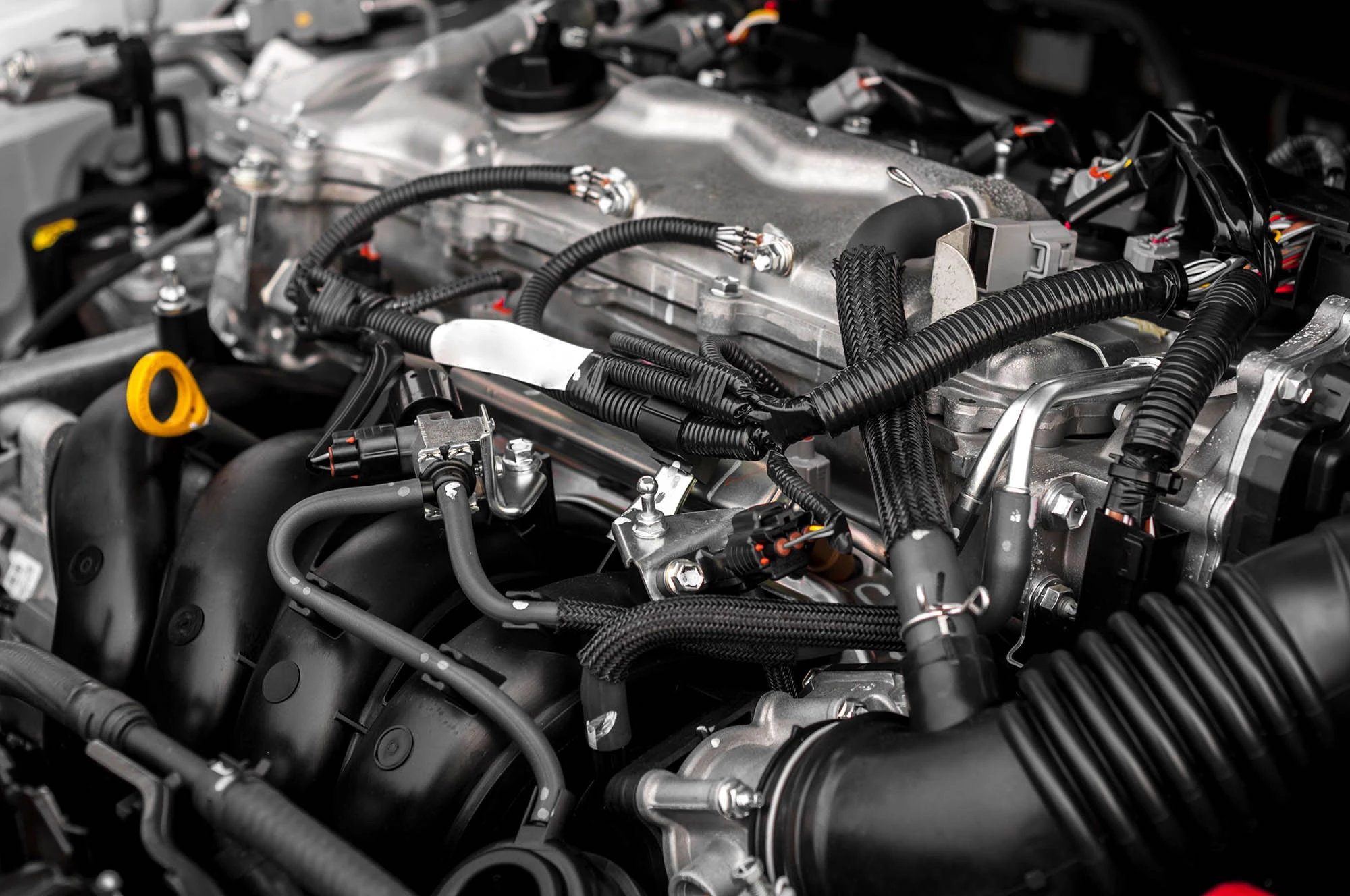

On the Engine

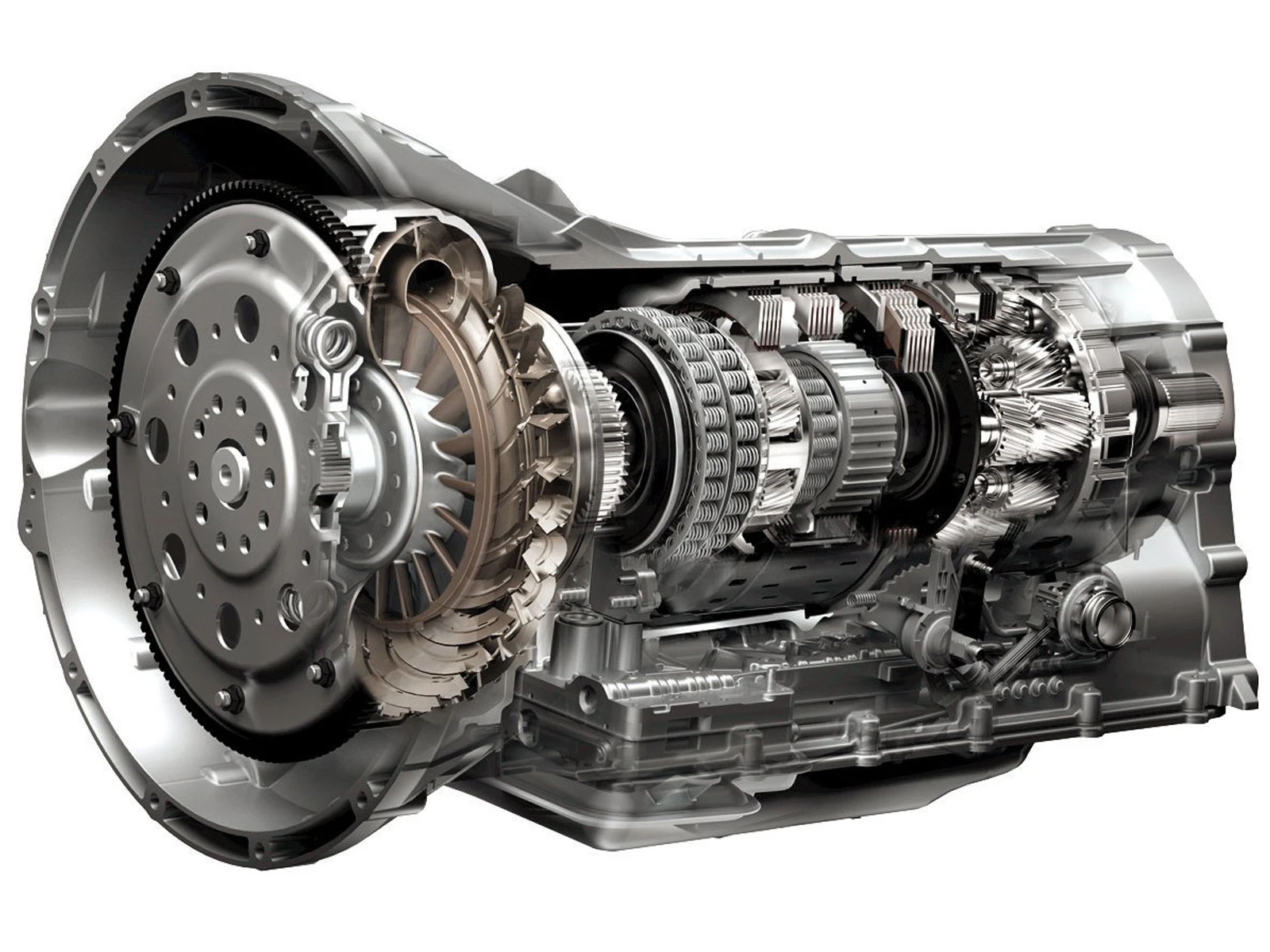

On the transmission

Automotive Under the Hood

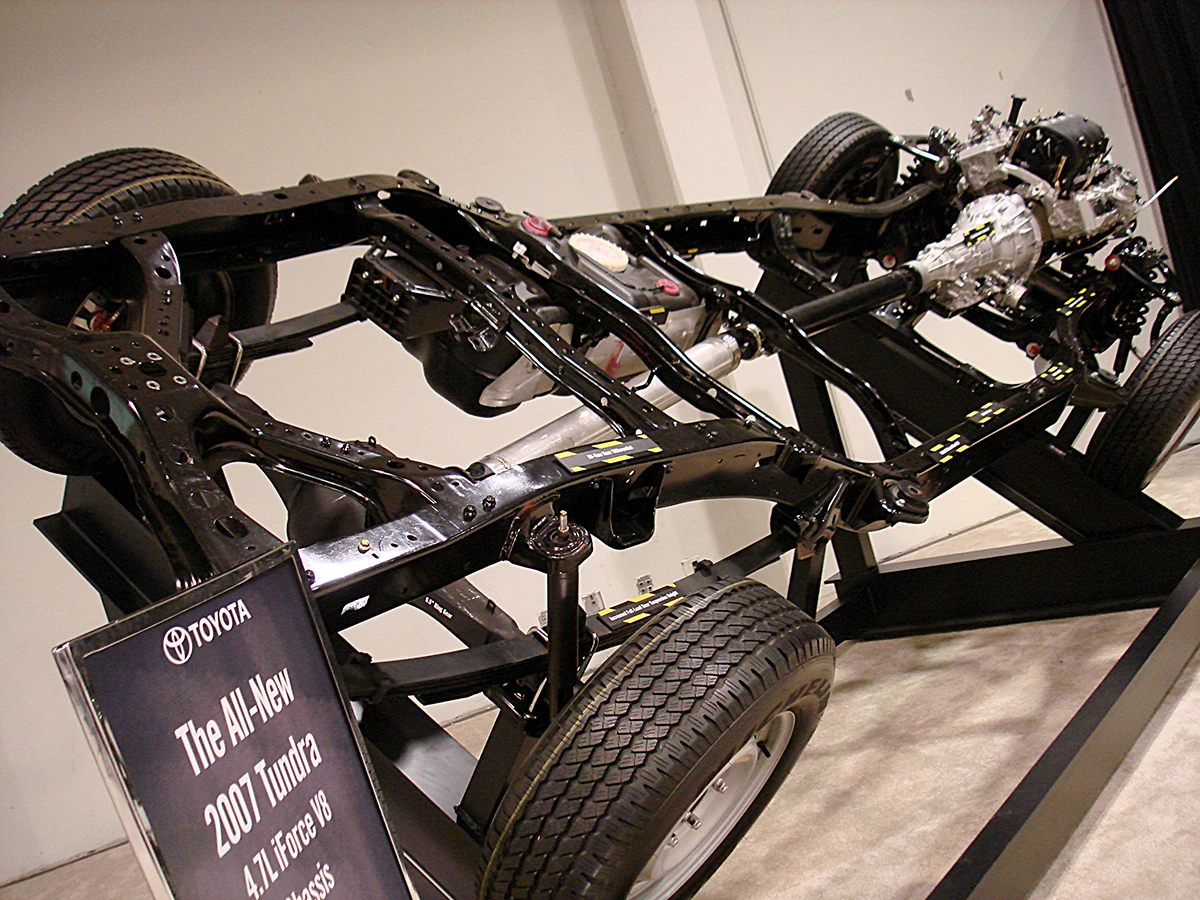

On the Chassis

In the Cab

in the heavy duty

Our Workshop Overview

EDM Mirror Processing

EDM Parts

Slow-feeding wire cut machine

CNC Machine

Plastic Injection Machine

Automatic production Line

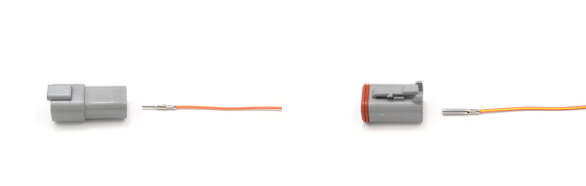

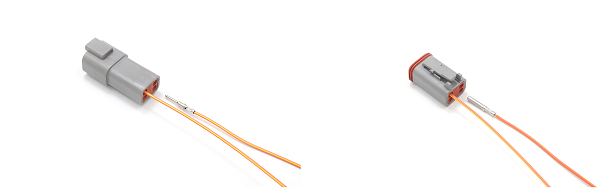

How to instructions

Step 1 Crimp the terminal and do the pull-out test to make sure the crimpings are completed

step 2 Crimping terminal and matched connector

Step 3 Insert the terminal to the connectors

Step 4 finished the connecting.