Building a Robust Home for Your Core Circuitry: An In-Depth Look at the DEUTSCH PCB Enclosure Selection Guide

In industries such as industrial automation, heavy machinery, rail transportation, and aerospace, electronic equipment faces extreme challenges—vibration, shock, moisture, dust, and extreme temperatures are ever-present. How can you ensure the stable operation of printed circuit boards (PCB) in such environments? The answer lies in selecting a rugged and reliable “home” for them. DEUTSCH PCB enclosures are top-tier solutions designed precisely for this purpose.

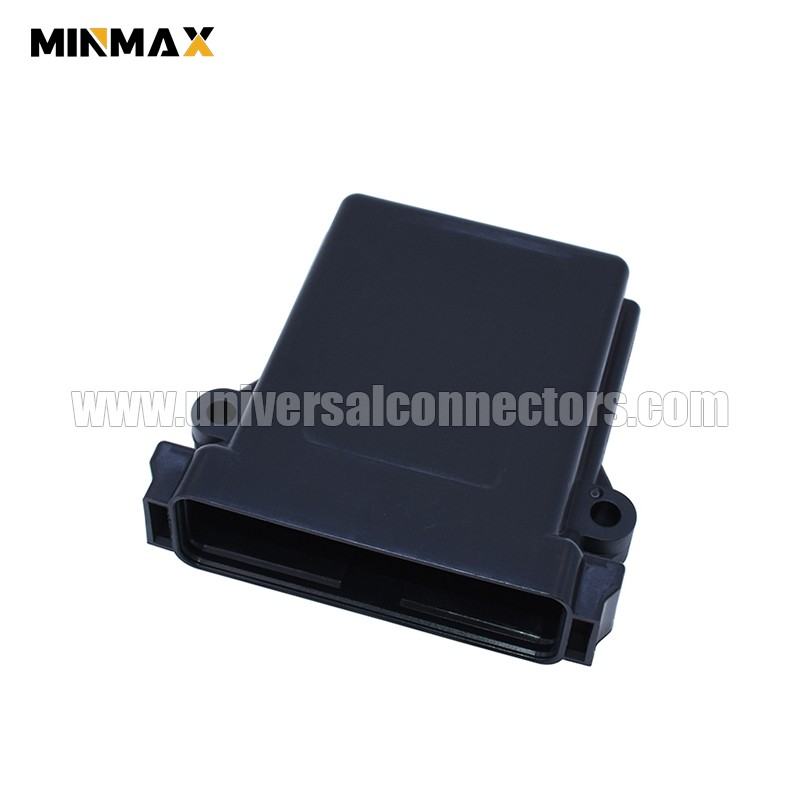

Today, we will take the EEC-325X4B, a classic model, as an example to explore the industrial applications of DEUTSCH PCB enclosures and provide a detailed explanation of how to choose the appropriate complementary components.

DEUTSCH PCB Enclosures: Synonymous with Robust Protection

The DEUTSCH PCB enclosure series is more than just a container—it is a fully integrated solution with connection management, ensuring your PCB remains protected under the harshest conditions.

Product Links:

DEUTSCH PCB Enclosure Series: https://www.universalconnectors.com/deutsch-accessories/enclosure/

EEC-325X4B Product Model: https://www.universalconnectors.com/product/eec-325x4b-k-12-24-36-48-position-black-deutsch-eec-series-enclosure/

What Are the Industrial Applications of the EEC-325X4B?

The EEC-325X4B is a four-pin aluminum PCB enclosure designed to meet high environmental standards.

Construction Machinery and Heavy-Duty Vehicles: Used in engine control units (ECU), sensor interface modules, and cabin control systems. Effectively withstands intense vibration and temperature fluctuations.

Industrial Automation: Protects PLC I/O modules, motion controllers, and drives in factory environments from oil, coolant, and metal dust.

Rail Transportation: Applied in onboard signal processing units and monitoring equipment, meeting the stringent safety and reliability requirements of the rail industry.

Energy and Power: Provides sealed housing for power monitoring and protection equipment in wind farms or substations.

Outdoor and Harsh Environments: Suitable for any application requiring a rugged, sealed, and reliable electronic packaging solution.

How to Select Complementary Components for Your EEC-325X4B

Choosing the right complementary components is critical to ensuring the integrity and reliability of the entire system. The EEC-325X4B enclosure serves as a platform, and you need to configure it with a compatible connector system. It is typically paired with DEUTSCH DTM series connectors.

1.Male Connector

This component is installed on the cable harness end and plugs into the enclosure.

How to Select: Choose a DTM series plug that matches the interface specifications of the EEC-325X4B.

Example: DTM13-12PA-12PB-R008 :https://www.universalconnectors.com/product/dtm13-12pa-12pb-r008-male-24-position-sealable-2-row-wire-cable-for-new-energy-vehicles/

2. Female Connector

How to Select: Select a female connector that matches the DTM13-12PA-12PB-R008 plug interface. (Note: Ensure compatibility in product series, pin count, and slot configuration.)

Example:

3.Terminals

Terminals are the metal contacts that are crimped to the wires and inserted into the female receptacle.

How to Select:

Type: Female terminals are required, as they are inserted into the female receptacle.

Size: Select the terminal wire gauge (e.g., 20 AWG, 16 AWG) based on your current requirements. The EEC-325X4B typically uses standard DEUTSCH DTM series female terminals.

Example:

CKK002-1.2FNK1 :https://www.universalconnectors.com/product/1062-20-0122-female-crimping-dtm-contact-0-35-1-5-mm%c2%b2-22-16awg-nickel-plating/

CKK002-1.2FNK1-G :https://www.universalconnectors.com/product/1062-20-0122-female-crimp-contact-0-35-1-5-mm%c2%b2-22-16awg-selective-gold-plating/

Tool: Use a crimping tool to ensure crimping quality.

Example: DT-RT1 :https://www.universalconnectors.com/product/dt-rt1-black-deutsch-dtm-extraction-tools/

4.Wedgelocks

The Wedgelocks are a critical component of the connector, ensuring the plug and receptacle remain securely locked together even under severe vibration.

How to Select: Typically, choose the corresponding DTM series latch.

Example: WM-12S :https://www.universalconnectors.com/product/wm-12s-female-12-pins-orange-deutsch-dtm-wedage/

5.Sealing Plug

Sealing plugs are used to seal unused positions in the female receptacle, maintaining the overall ingress protection rating of the connector.

How to Select: These can usually be found in the “Accessories” or “Related Products” section of the female receptacle product page.

Example: 0413-204-2005 :https://www.universalconnectors.com/product/0413-204-2005-automotive-connector-sealing-plug-pbt/