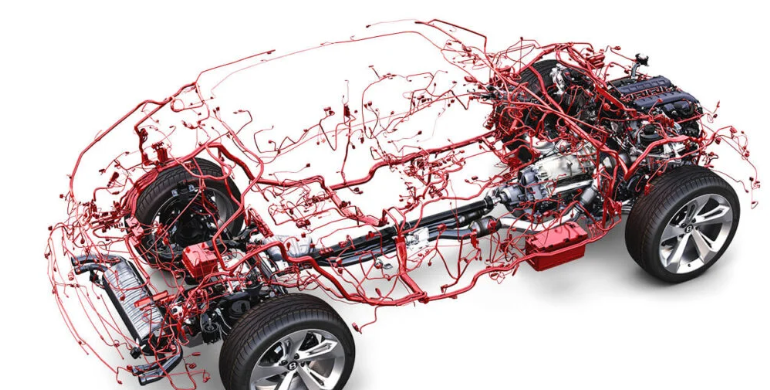

In the automotive industry, the reliability of electrical systems depends heavily on how wires are connected. Whether you’re working on a custom harness, repairing a circuit, or designing a new ECU interface, the method of connection is critical to performance, safety, and durability.

At MINMAX Co., Ltd., with decades of experience in manufacturing automotive connectors, wiring harnesses, and related components, we’ve refined the best practices for connecting automotive wires. Here’s what we’ve learned:

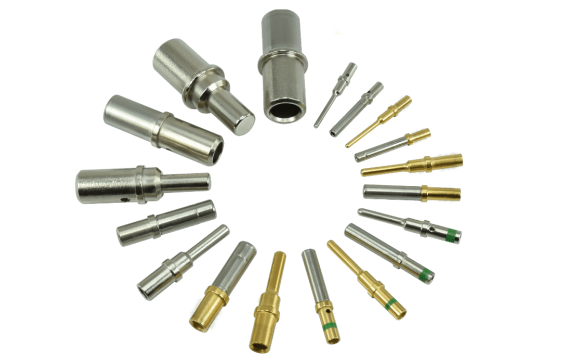

1. Use High-Quality Connectors and Terminals

Not all connectors are created equal. The best connections start with high-precision terminals and connectors made from superior materials. At MINMAX, we produce and supply over 10,000 types of connectors, including PCB/ECU series such as AMPSEAL 1.5, JAE, and Molex CMC. These are designed to withstand vibration, temperature changes, and moisture—common challenges in automotive environments.

Tip: Always choose connectors that are compatible with automated assembly processes to ensure consistency and reliability.

2. Implement Automated Wiring Harness Assembly

Automation isn’t just for efficiency—it’s for quality. Our wiring harness factory uses automated cutting, stripping, and terminating processes to ensure every wire is prepared accurately. This reduces human error and enhances the repeatability of each connection.

3. Follow a Strict Quality Control Process

A reliable connection isn’t just about the parts—it’s about the process. At MINMAX, we enforce a multi-stage quality control system:

First Check during preparation and assembly

QC Inspection during and after production

Final Audit before shipment

We also use FIFO (First-In-First-Out) systems and advanced ERP and CRM platforms to track every order from receipt to delivery.

4. Leverage PCB and ECU Connectors for Modern Vehicles

Modern vehicles rely heavily on electronic control units (ECUs). Using specialized PCB and ECU connectors ensures stable signal transmission and resistance to electromagnetic interference. We’ve focused heavily on these products in recent years, offering both standard and customized solutions.

5. Don’t Overlook the Accessories

Seals, terminals, and pins are not “just accessories.” They are essential for waterproofing, corrosion resistance, and mechanical stability. For example, all our seals are compatible with automated machines and have been supplied to OEMs like Geely Automotive.

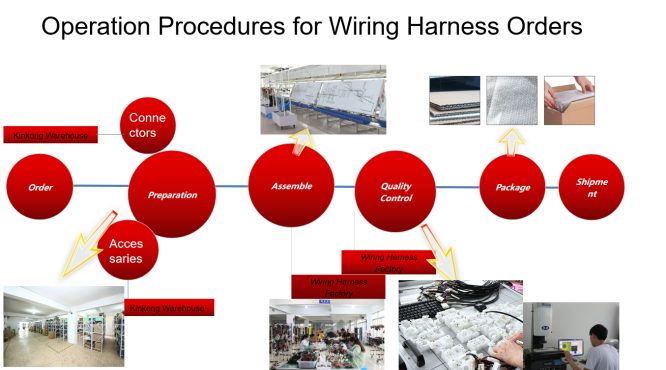

6. Adopt a Systematic Approach from Order to Delivery

A well-connected wire is part of a well-connected system. Our operational workflow includes:

Order → Preparation → Assembly → QC → Packaging → Shipment

In-house QC at the MINMAX warehouse acts as the last firewall before delivery.

Every customer complaint is documented in a Customer Complaint Report to prevent future issues.

7. Certifications Matter

We operate under:

ISO 9001:2015

IATF 16949 (formerly TS 16949)

SGS certifications

These standards ensure that every product—and every wire connection—meets international quality and safety benchmarks.

Conclusion

The best way to connect automotive wires is to combine high-quality components, automated precision, rigorous quality control, and systematic processes. At MINMAX and our subsidiary MINMAX, we’ve built our reputation on this integrated approach—serving the tuning, aftermarket, and OEM sectors worldwide.

Whether you’re designing a new harness or sourcing reliable connectors, remember: a secure connection today prevents failure tomorrow.